As best as I can recall, I’ve never coined a phrase with any staying power.

As best as I can recall, I’ve never coined a phrase with any staying power.

Until now.

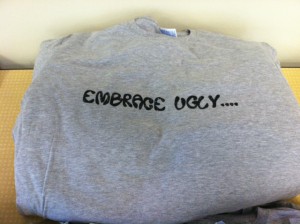

And, my phrase has been purposely captured on a T-shirt, by someone other than a close relative. It’s not quite like having my words recorded indelibly in marble and situated in the Parthenon, but I’ll take it.

Enough gloating, what’s the phrase and what is its etymology?

“Embrace ugly.”

It’s a term that I have used frequently with a particular client. Frequently - as in multiple times per day, even multiple times per hour. I repeated the phrase, not only because of its self-entertainment value (yes, I do that), but more importantly to break the client’s paradigm.

You see, they were (note the past tense) chronic and debilitating perfectionists.

Now, striving for perfection is part and parcel of Lean Thinking (by way of Womack and Jones). The Lean Enterprise Institute lists the fifth step, “As value is specified, value streams are identified, wasted steps are removed, and flow and pull are introduced, begin the process again and continue it until a state of perfection is reached in which perfect value is created with no waste.”

However, the intent is to aggressively pursue continuous improvement – by frequently and rigorously spinning the PDCA (plan-do-check-act) wheel.

Perfectionists however have a very difficult time getting around the wheel and, in essence, missing the benefits of failing faster. Perfectionists tend to have their own version of the wheel, something like PPPPPDDDDD, or Plaaaaaaannnnnn, then Dooooooooooo. “C” and “A” are, often accidentally and ironically excluded from the perfectionists wheel.

Why?

Because after investing so much time planning and then investing in the perfect “Do,” (impossible, by the way) there is little time or money or will left to make meaningful adjustments. The victims (a.k.a. stakeholders) are often doomed to a life with less than optimal fixtures, equipment, facilities, etc.

How many times have you seen expensive underutilized stainless steel equipment, nicely laminated work surfaces that workers do not like, pricey, oversized extruded aluminum workstations, and flashy, but useless tooling? Stuff that unfortunately was not designed or developed with important things in mind like takt time, footprint, PM’s, flows (of people, materials, supplies, information, tooling, etc.), visual control and line of sight (i.e., can you see over and around it easily?), ergonomics, scrap, etc.

While lean folks apply 3P (production preparation process) concepts like 7 different ways and seek to down-select to the top three or so and then trystorm their way into the best using sub-scale and full scale models made of cardboard, plywood, and PVC, perfectionists are machining or building the perfect design in expensive materials.

In short, lean folks embrace ugly. They revel in trystorming, in learning, in rapid PDCA. Ugly is synonymous with the quick and the dirty.

Which is exactly why I kept repeating, “embrace ugly,” until my friends were repeating the same and then finally breaking away from the suffocating, expensive, lethargic legacy of perfectionism.

…and now, they’re wearing the words on their shirts.

A couple of quotes:

“Quick and dirty is better than slow and fancy.” - Taiichi Ohno

“A good plan implemented today is better than a perfect plan implemented at some unspecified

time in the future.” - General George S. Patton

Related posts: Kaizen Principle: Be Like MacGyver, Use Creativity Before Capital!, Lean Space – Some Thoughts and 10 Questions