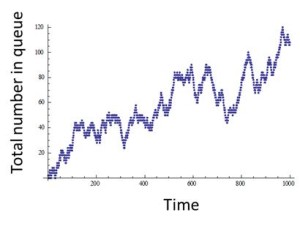

Flow is a key lean principle. We should relentlessly pursue a state in which value flows smoothly, without interruption to the customer. But how can this be achieved? Assuming that we have adequate system stability, repeatability, and other important "ilities," as well as a design and culture that facilitates continuous flow (admittedly, really difficult stuff), the answer is amazingly simple – match capacity to demand. So, if you have 10 customer requests your capacity should be 10 customer requests, and if the demand is 1,172 customer requests the capacity should be 1,172 requests. Notice that we didn’t say that average capacity should equal average customer demand, instead we said it should equal customer demand. Actual trumps average in the queue math world. Why? If your average capacity equals average customer demand, the queue can grow to be infinitely large. Whereas, if capacity equals actual customer demand, there is no queue. Every customer request is immediately processed. Don’t believe us? Consider the following example:  In our simple example, the average capacity is equal to the average customer demand. Unfortunately, here is what can happen:

In our simple example, the average capacity is equal to the average customer demand. Unfortunately, here is what can happen:  The total number of requests in the queue grows without bound. The variation in the input swamps the capacity of the system even though the average system capacity is equal to the average customer demand. So what’s the answer, how much processing capacity is needed in the system for situations where the instantaneous capacity cannot flex to be equal to instantaneous customer demand? Well, it depends. It depends on the specifics of each queue and on the tolerance level to different queue sizes. Some value streams, by design, are fill-and-drain processes, where a large number of items are put into the queue and then are processed. For example, unloading a truckload of raw materials can be thought of as a fill-and-drain process. If the truck needs to be unloaded quickly, then there needs to be a lot of capacity (i.e. all hands on deck) to unload the truck. But if the truck can stay for a while, then the number of people unloading the truck can be smaller. So, the best answer we have found to the imponderable questions of: "Why is this line so long?" and "How much capacity do I need for this queue?" is to simulate the value stream over a number of different scenarios that reflect real-life variation...and observe the queue dynamics. Such an approach will often dispel any notion that a system capacity that is equal to average customer demand is sufficient.

The total number of requests in the queue grows without bound. The variation in the input swamps the capacity of the system even though the average system capacity is equal to the average customer demand. So what’s the answer, how much processing capacity is needed in the system for situations where the instantaneous capacity cannot flex to be equal to instantaneous customer demand? Well, it depends. It depends on the specifics of each queue and on the tolerance level to different queue sizes. Some value streams, by design, are fill-and-drain processes, where a large number of items are put into the queue and then are processed. For example, unloading a truckload of raw materials can be thought of as a fill-and-drain process. If the truck needs to be unloaded quickly, then there needs to be a lot of capacity (i.e. all hands on deck) to unload the truck. But if the truck can stay for a while, then the number of people unloading the truck can be smaller. So, the best answer we have found to the imponderable questions of: "Why is this line so long?" and "How much capacity do I need for this queue?" is to simulate the value stream over a number of different scenarios that reflect real-life variation...and observe the queue dynamics. Such an approach will often dispel any notion that a system capacity that is equal to average customer demand is sufficient.

Queue Math and the Danger of Averages

Blog contents Copyright ©2009-2024 Mark R. Hamel. The views expressed herein are solely personal views and not those of associates, clients or employers. Comment functionality has been deactivated. Please contact [email protected] with any questions or comments.