Lean culture is largely defined by, or at least manifested in, engaged and empowered employees practicing voluntary kaizen. Engagement can be measured in a number of ways, but perhaps one of the most telling is the number of implemented suggestions per employee per year.

Lean culture is largely defined by, or at least manifested in, engaged and empowered employees practicing voluntary kaizen. Engagement can be measured in a number of ways, but perhaps one of the most telling is the number of implemented suggestions per employee per year.

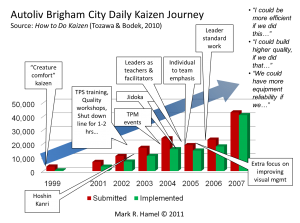

A while back, I developed an outline of Autoliv Brigham's daily kaizen journey (see figure below) based upon information within the book, How to Do Kaizen. Autoliv's story is extremely compelling.

Often engagement evolves as employee line of sight evolves. Line of sight is my euphemism for the scope of the employee's ability AND desire to see, to understand, and to care beyond the self. Successful organizations are clearly much more than a loose confederation of individuals.

Start Somewhere

Lean transformations have to start somewhere. Many times it starts with an average employee line of sight that extends about as far as "self." If that's the case, then the lean leaders need to engage right there.

What does that mean?

Well, if the employee cares little beyond the self, then train and involve them in creature comfort kaizen for themselves (as finder and fixers of the problems). Recognize their improvements and their creativity and share it with others. The four-fold goal of kaizen is easier, better, faster, and cheaper…in that order. Start with easier and build from there.

This develops the employee’s kaizen capability and, if done effectively, their appetite and eyes for kaizen. But don’t stop there. Expand the context for kaizen. Extend the line of sight beyond just the self.

Expand the Line of Sight

Most employees work within some sort of natural work team – folks who typically work together on a daily basis towards some common purpose. (Admittedly, sometimes the team in which they are a member is less than “natural” and formed for management convenience and economics, not the flow of value. Not optimal, but often it’s still manageable.) There are a number of things that the lean leader can do to facilitate greater engagement, including:

- Deploy a daily accountability process. Effective lean management systems include the use of tiered meetings to review team performance versus targets, plan for the next 24 hours, and identify issues, barriers and countermeasures. It drives shared understanding of process performance, foments dialogue, and "pulls" suggestions.

- Provide more lean and team effectiveness training and time to use it. The more actionable knowledge about lean and how to better perform as a team, the better. While a lot of daily kaizen can happen in the margins (breaks, before shift and after shift), collaborative efforts are most likely to happen if some time is provided on a periodic basis during working hours.

- Leverage performance management. It's a game-changer when the criteria on how people are evaluated and compensated includes team and company outputs as well as desired lean behaviors.

- Involve employees in organized kaizen. Kaizen events and facilitated kaizen circle activities will further develop the organization's problem-solving muscle and expand awareness and ownership.

- Leaders transition to teachers and facilitators. Perhaps the toughest transformational challenge is flipping the organizational pyramid "upside down" so that the leaders become enablers, not bottlenecks.

- Apply lean tools and systems that drive employee involvement. For example: 5S is an supremely intuitive and engaging tool...and it can provide near instant gratification. Visual controls, among other things, share information with virtually every stakeholder. Talk about line of sight! TPM, specifically autonomous maintenance, by its very nature requires direct involvement and ownership.

This is just the tip of the iceberg.

What do you do to expand the line of sight and engagement within your organization? How does that drive daily kaizen?

Related posts: Book Review: How to Do Kaizen, Lean Management Systems and Mysterious Performance Metrics, Easier, Better, Faster, Cheaper…in that Order