When discussing lean math with other folks, I often get some less than optimal responses. Of course, much of the time it's probably me!

In any case, this is how I would characterize the more non-value-adding responses to the subject.

- Apoplectic. You know, the math anxiety induced stroke. Some people would be more than happy living in a math-free world. The mere mention of numbers and formulas can lead to hyper-ventilation, lack of focus, and non-productive hand-wringing. Relax, you probably won't be using this math to save any lives or deliver any babies.

- Catatonic. As in an eyes glazed over kind of stupor. This stupor can be induced by either boredom (math ain't too exiting) or it can be a coping mechanism that convincingly signals to co-workers that they better take this one because my brain has seized up. Often the catatonic state is preceded or followed by apoplexy.

- Obsessive. Some folks get into the math so much that they lose any notion of balance between theory and reality. Lean-oriented math is a vehicle for improvement. It is not the end game...and the best application of "belts" is to hold up one's pants.

- Contentious. And then there are those who would like to argue every aspect of the math, often not because it matters, but because it's a venue to establish intellectual superiority. During these arguments (or the contentious one's monologue), the other people tend to look around for possible escape routes.

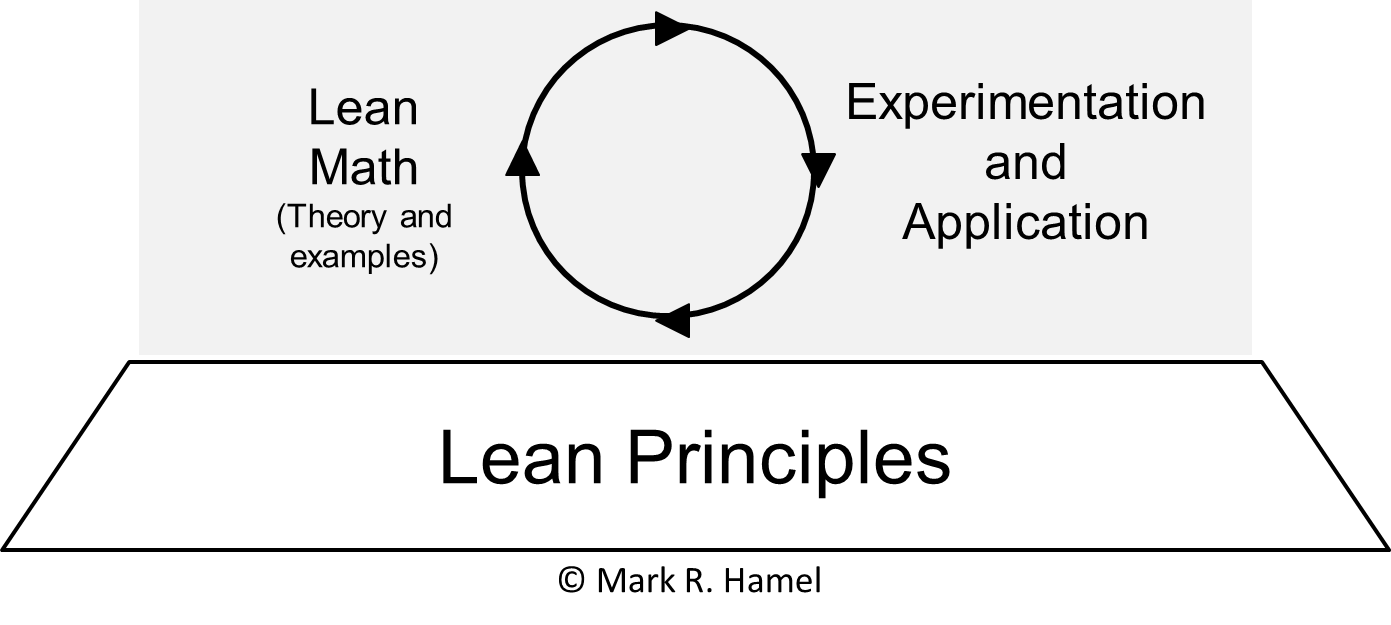

My simple suggestion to everyone is two-fold: 1) never stray from lean principles, and 2) get your hands dirty.

Indeed, lean principles are the foundation. You can't trump things like respect, humility, flow, pull, stop and fix, etc.

The notion of experimentation and application reflected in the figure below equates to getting your hands dirty.

Certainly, some lean math formulas can be intimidating, we can’t get trapped into inactivity – the old analysis paralysis. Lean is largely about learning by doing. This is where, depending upon the implementation risk, trystorming and simulation are critical strategies for moving forward.

So, for example, if you’re looking to implement a mixed model production kanban, it probably makes sense to do some table top simulations (with proxy kanban cards), and run through several weeks of actual historical demand…in excruciating detail as you test supermarket levels, stock-outs, emergency kanbans, impacts of changeovers, unplanned downtime, etc. Try to see when and where the system breaks down…then make adjustments and do it again and again (think plan-do-check-act, PDCA).

When the implementation risk is less significant, like developing a new performance metric, the trystorming or simulation may be close to zero. Put it out there and apply PDCA in real time.

“Use” the math. As fellow lean practitioners, we’re all looking to effect continuous improvement. A 5% or 10% improvement today is better than a 80% improvement at some unspecified time in the future.

So, in a word, get over your lean math phobias, have some fun and never violate lean principles.