Little’s Law, named after John D. C. Little and his 1960 queuing proof, characterizes the dynamic relationship between work-in-process inventory (WIP), throughput rate, and lead time within a reasonably stable system. The “system” can be that of a process, cell, or line and can extend to one or more value streams. The Law, like all core lean principles, is universal and applies to all industries.

If the system has fixed capacity, lead time and WIP are proportional, meaning that if there is an increase or decrease in WIP, there is a commensurate impact on lead time, and vice versa. Throughput rate represents the average output of the system per unit of time and may be increased by improving bottleneck utilization and/or bottleneck rate. Lead time is the average time span for each unit to move completely though the system, including all process time and queue time, from its initial introduction to its final completion and release from the system. The “unit” here, can be an assembly, insurance claim, patient, etc.

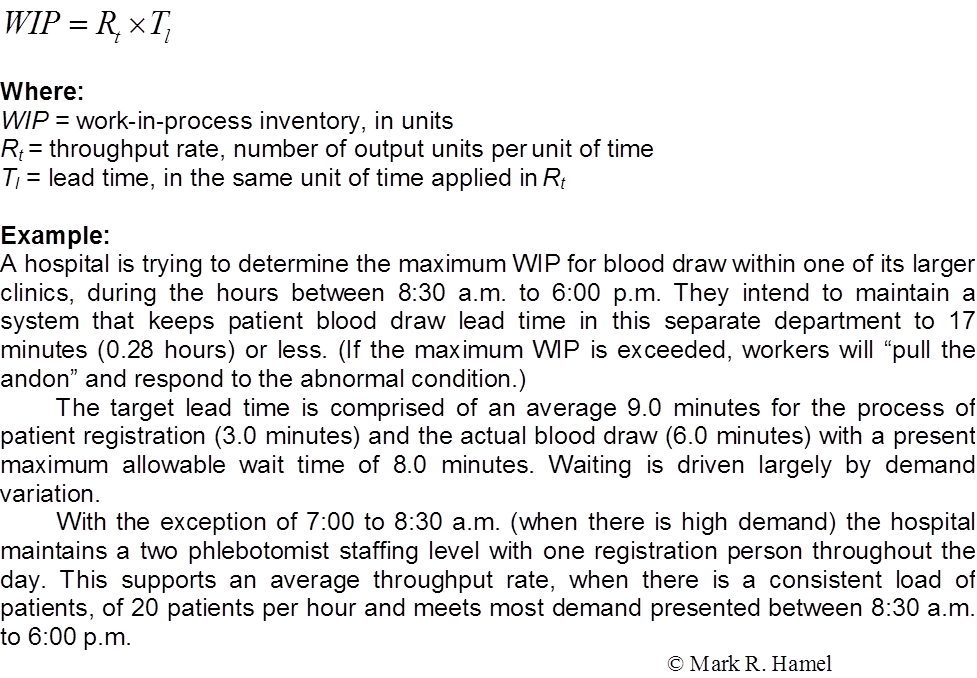

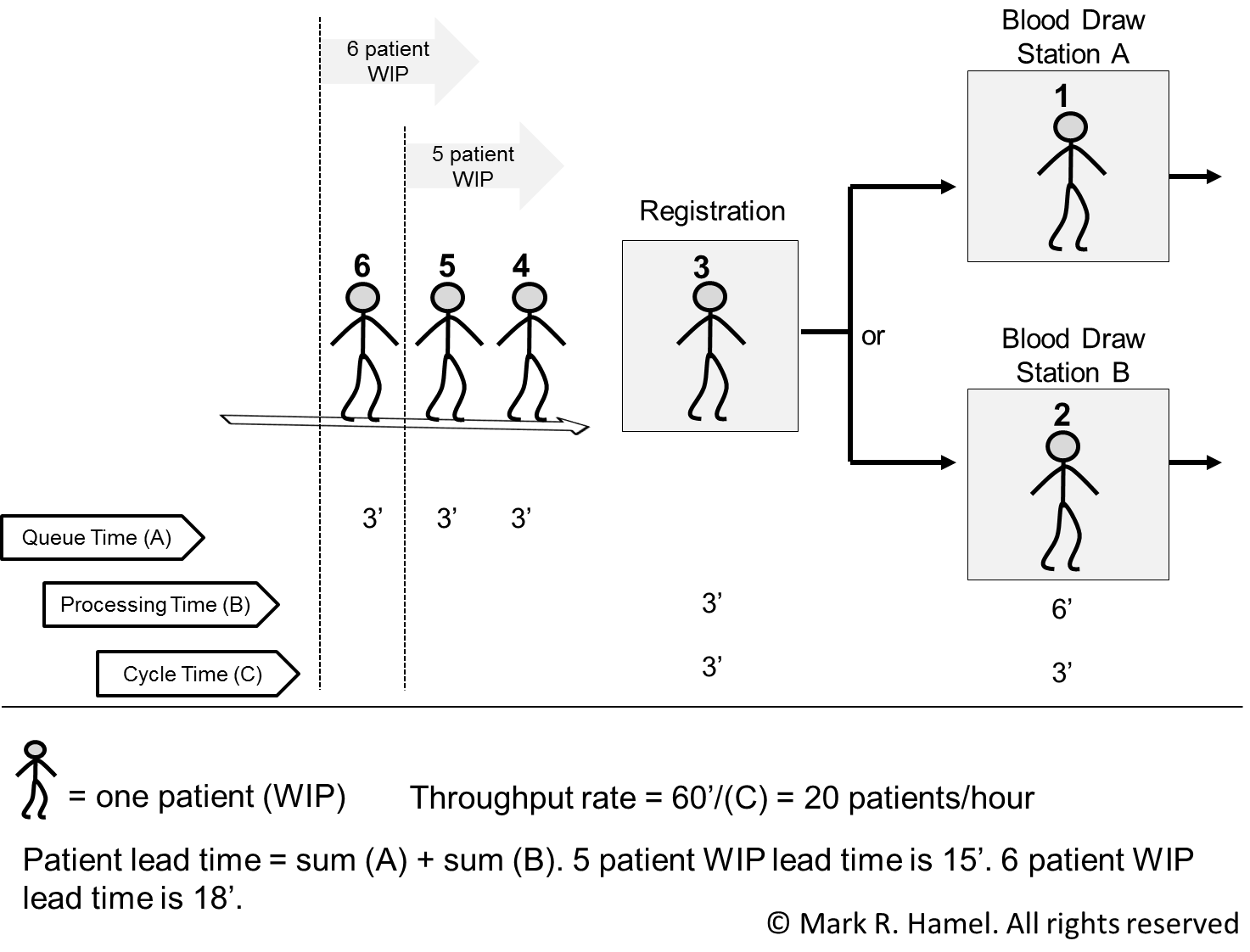

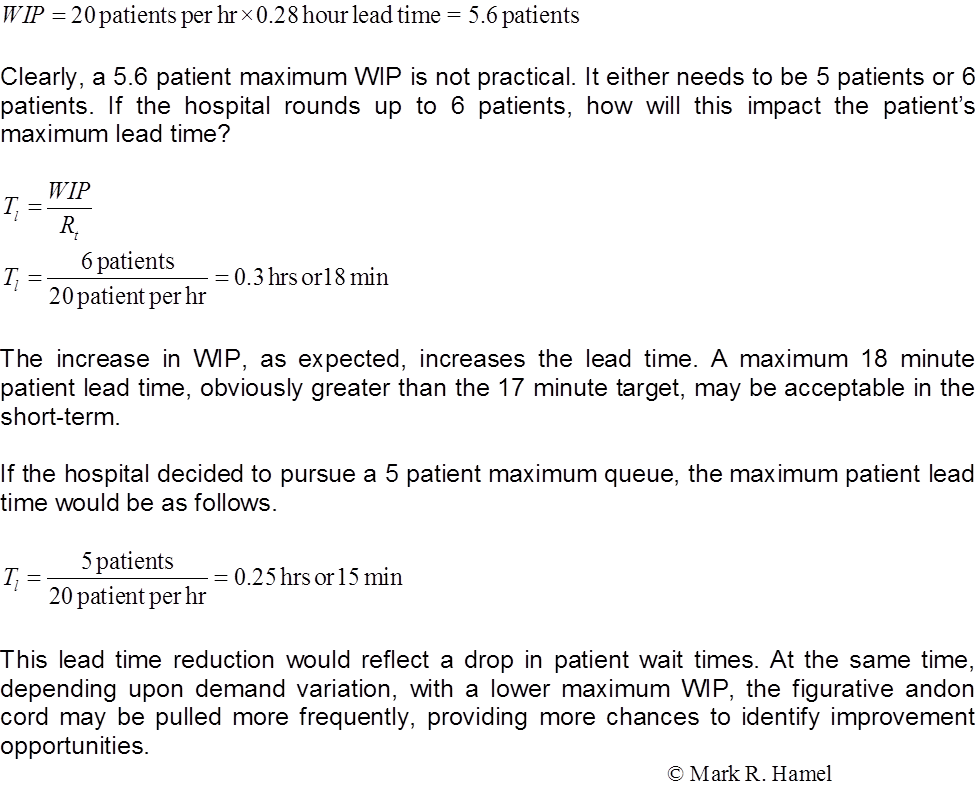

The math for Little's Law follows: