Life happens. Sometimes it rains on wedding days. Sometimes a supplier misses a ship date, and sometimes there are glitches in our processes. The challenge for lean practitioners is what to do about this – especially since all of these things could happen.

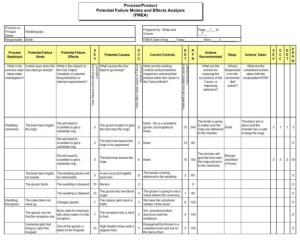

One good answer is to constuct a Failure Modes and Effect Analysis (FMEA). This can be done for a process, or a new or existing product. The basic concept is to identify all of the potential failure modes and then rank them according to risk. Risk Priority Numbers (RPNs) are used to assess the risk of each failure mode.

A Risk Priority Number (RPN) is calculated as follows:

That is, the risk associated with any failure mode is comprised of three parts:

- Severity – The more severe the failure mode, the higher the risk.

- Likelihood – The more likely the failure mode, the higher the risk.

- Detectability – The harder it is to detect and control the causes and conditions of a given failure mode, the higher the risk.

Usually each of these factors is graded on a 0 to 10 scale. For Severity and Likelihood, the more severe the consequences or the more likely the failure mode is to occur, the higher the score. With Detectability, the harder the cause is to detect and control, the higher the score.

Once Risk Priority numbers have been established for all of the failure modes, the next step is to develop a risk mitigation strategy for the high risk items. That way these risks can be addressed proactively. The risk mitigation strategies are given a predictive Risk Priority Number (pRPN) which estimates what the risk priority number will be once the risk mitigation strategy has been put in place. These risk priority numbers can be helpful for identifying which risk mitigation strategies to implement first.